This article presents the structural concept of the shaft support system for vertical shaft machines, describing its design features, manufacturing process, and the functional role of the rubber element positioned between the bushings. The study also examines the improved lubrication system and explains the purpose of shaping the lower inner part of the housing in a hemispherical form, emphasizing the damping function provided by the rubber damper installed in this area. In addition, the paper investigates the twist angle of the helical grooves formed along the shaft in the direction opposite to shaft rotation, the operating rotational speed, and the influence of elastic components within the support assembly on deflection behavior. Experimental test results obtained using weight-based wear measurement techniques are presented to evaluate the durability and performance characteristics of the improved support structure.

| Published in | American Journal of Mechanics and Applications (Volume 12, Issue 4) |

| DOI | 10.11648/j.ajma.20251204.15 |

| Page(s) | 102-108 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Housing, Bushing, Bearing, Rubber Damper, Shaft, Base Plate, Helical Grooves, Lubricating Material

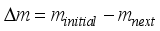

(1)

(1)  -Weight of the component before testing (g).

-Weight of the component before testing (g).  - Weight of the component after testing (g).

- Weight of the component after testing (g).  - Mass loss (g).

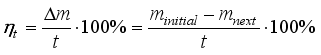

- Mass loss (g).  (2)

(2)  (3)

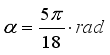

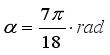

(3)  ,

,  and until

and until  It can be observed that when increased, the wear rate of the inner part of the composite bushing ranged from 1.48% to 1.31%, achieving a reduction of up to 0.17% (Figure 9).

It can be observed that when increased, the wear rate of the inner part of the composite bushing ranged from 1.48% to 1.31%, achieving a reduction of up to 0.17% (Figure 9).  fixed, and the shaft rotates at 35–45 rpm, an increase in the stiffness coefficient of the elastic element in the shaft support resulted in the wear rate of the bronze part in the support rising from 1.33% to 1.47% (Figure 10).

fixed, and the shaft rotates at 35–45 rpm, an increase in the stiffness coefficient of the elastic element in the shaft support resulted in the wear rate of the bronze part in the support rising from 1.33% to 1.47% (Figure 10). Weight of the Component Before Testing(g) | |

Weight of the Component After Testing (g) | |

Mass Loss (g) |

| [1] | Sh. A. Shoobidov. Machine Parts. Textbook. Tashkent: “O‘zbekiston Milliy Ensiklopediyasi” State Scientific Publishing, 2014; p. 374. |

| [2] | A. Jo‘rayev, R. Tojiboyev. Applied Mechanics. Tashkent: “Fan va Texnologiya”, 2007; 288 p. |

| [3] | V. A. Dmitriev. Machine Parts: Fundamentals of Calculation and Design of Machines. Leningrad: “Sudostroenie”, 1970, pp. 641–649. |

| [4] | A. J. Jo‘rayev et al. Theory of Machines and Mechanisms. Tashkent: Gafur G‘ulom, 2004; p. 408. |

| [5] | John J. Uicker, Jr. Theory of Machines and Mechanisms. New York: Oxford University Press, 2017; 978 pp. |

| [6] | P. I. Orlov. Fundamentals of Design, Vol. 2. Moscow: Mashinostroenie, 1988, pp. 372–373, 385–387, 399-404. |

| [7] | Thrust Sliding Bearing Assembly. UZ FAP 2752. Published: 26.06.2025. Bulletin No. 6(291). |

| [8] | Sh. Kenjaboev, N. Muydinova, A. Akbarov, F. Nishonov. Thrust Sliding Bearing Assembly. Scientific Journal Mechanics and Technology, No. 3(20), 2025. |

| [9] | Sh. Kenjaboev, N. Muydinova, A. Akbarov, F. Nishonov. Thrust Sliding Bearing Assembly. Scientific Journal Science, Research, and Development, 2025, No. 4(12). |

| [10] | T. B. Minigaliev, V. P. Dorozhkin. Technology of Rubber Products: Textbook. Kazan: Kazan State Technological University Publishing, 2009; 236 p. |

| [11] | O. Ikromov. Tribology. Friction and Wear. Tashkent: Uzbekistan, 2003; 336 p. |

| [12] | D. N. Garkunov. Tribology: Design, Manufacturing, and Operation of Machines. Moscow: MSHA Publishing, 2002; 626 p. |

| [13] | A. Djuraev, Sh. Kenjaboev, A. Akbarov. Development of Design and Calculation of Frictional Force in Rotational Kinematic Pair of the Fifth Class with Longitudinal Grooves. International Journal of Advanced Research in Science, Engineering and Technology, India, 2018, No. 9, pp. 6759-6763. |

| [14] | I. V. Kragelsky. Friction and Wear. Moscow: Mashinostroenie, 1968; 482 p. |

| [15] | A. V. Lavrin, V. B. Bolyakin, V. B. Ossialalar. Experimental Study of Friction Torque in a Rolling Bearing under Shaft Misalignment. Proceedings of the Samara Scientific Center of the Russian Academy of Sciences, 2018, Vol. 20, No. 4-1, pp. 37-42. |

APA Style

Shukurjon, K., Nilufar, M., Alisher, A., Farkhod, N. (2025). Improvement of the Support Structure of the Working Body for a Vertical Shaft Machine and Its Experimental Test Results. American Journal of Mechanics and Applications, 12(4), 102-108. https://doi.org/10.11648/j.ajma.20251204.15

ACS Style

Shukurjon, K.; Nilufar, M.; Alisher, A.; Farkhod, N. Improvement of the Support Structure of the Working Body for a Vertical Shaft Machine and Its Experimental Test Results. Am. J. Mech. Appl. 2025, 12(4), 102-108. doi: 10.11648/j.ajma.20251204.15

@article{10.11648/j.ajma.20251204.15,

author = {Kenjaboev Shukurjon and Muydinova Nilufar and Akbarov Alisher and Nishonov Farkhod},

title = {Improvement of the Support Structure of the Working Body for a Vertical Shaft Machine and Its Experimental Test Results},

journal = {American Journal of Mechanics and Applications},

volume = {12},

number = {4},

pages = {102-108},

doi = {10.11648/j.ajma.20251204.15},

url = {https://doi.org/10.11648/j.ajma.20251204.15},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ajma.20251204.15},

abstract = {This article presents the structural concept of the shaft support system for vertical shaft machines, describing its design features, manufacturing process, and the functional role of the rubber element positioned between the bushings. The study also examines the improved lubrication system and explains the purpose of shaping the lower inner part of the housing in a hemispherical form, emphasizing the damping function provided by the rubber damper installed in this area. In addition, the paper investigates the twist angle of the helical grooves formed along the shaft in the direction opposite to shaft rotation, the operating rotational speed, and the influence of elastic components within the support assembly on deflection behavior. Experimental test results obtained using weight-based wear measurement techniques are presented to evaluate the durability and performance characteristics of the improved support structure.},

year = {2025}

}

TY - JOUR T1 - Improvement of the Support Structure of the Working Body for a Vertical Shaft Machine and Its Experimental Test Results AU - Kenjaboev Shukurjon AU - Muydinova Nilufar AU - Akbarov Alisher AU - Nishonov Farkhod Y1 - 2025/12/20 PY - 2025 N1 - https://doi.org/10.11648/j.ajma.20251204.15 DO - 10.11648/j.ajma.20251204.15 T2 - American Journal of Mechanics and Applications JF - American Journal of Mechanics and Applications JO - American Journal of Mechanics and Applications SP - 102 EP - 108 PB - Science Publishing Group SN - 2376-6131 UR - https://doi.org/10.11648/j.ajma.20251204.15 AB - This article presents the structural concept of the shaft support system for vertical shaft machines, describing its design features, manufacturing process, and the functional role of the rubber element positioned between the bushings. The study also examines the improved lubrication system and explains the purpose of shaping the lower inner part of the housing in a hemispherical form, emphasizing the damping function provided by the rubber damper installed in this area. In addition, the paper investigates the twist angle of the helical grooves formed along the shaft in the direction opposite to shaft rotation, the operating rotational speed, and the influence of elastic components within the support assembly on deflection behavior. Experimental test results obtained using weight-based wear measurement techniques are presented to evaluate the durability and performance characteristics of the improved support structure. VL - 12 IS - 4 ER -